| compressedair filter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Release time:2020-01-09 Browse volume:1664 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product introduction

Compressed air is a safe and reliable power source widely used in industrial activities. It is estimated that about 90% of enterprises use compressed air in all fields of operation. However, unlike gas, water and electricity, compressed air is produced on site, and users can control the quality and operating cost of compressed air. Compressed air is not a problem-free power source. In actual operation, all systems will encounter performance and stability problems. However, almost all of these problems can be attributed to pollution. These major pollution sources include: water vapor, condensed water, water mist (aerosol), atmospheric dust, microorganisms, rust, pipe spalling, liquid oil, oil mist (aerosol), and oil vapor. The biggest pollution in compressed air comes from the air sucked by the compressor, rather than from the compressor itself, as is generally believed. The most troublesome pollutant is water, which accounts for 99.9% of the liquid pollutants found in compressed air systems. High-efficiency compressed air filtration technology can not only remove solid particles and oil, but also remove water mist, which is the key to operating an efficient and cost-effective compressed air system.

Technical parameter

● Working pressure: 0.3~ 9.9MPa

● filtering accuracy: ~0.01um

● Residual oil content: ~0.001ppm

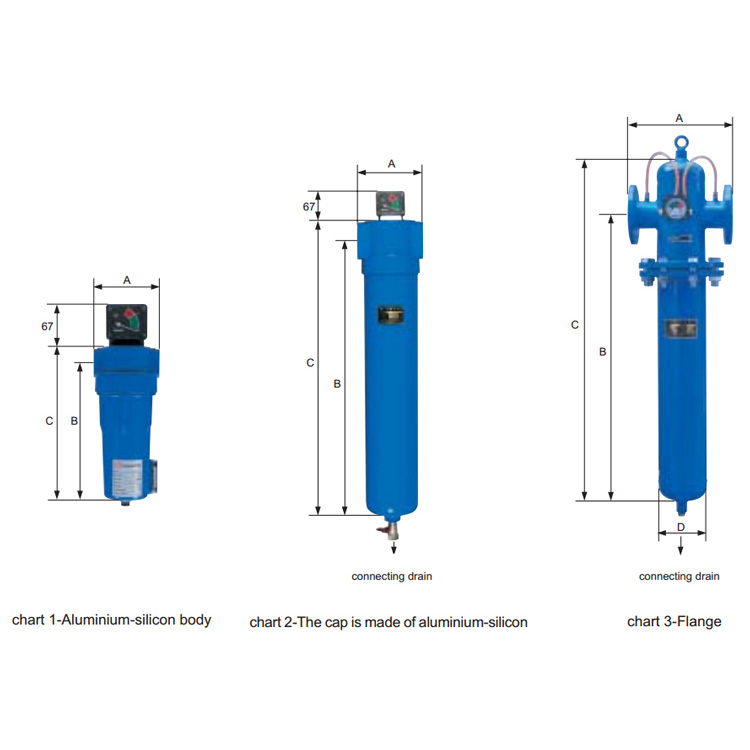

● Interface form: thread, flange, clamp and welding

● nominal size of interface: DN15~DN300

● interface standard: hgb shhgjbansijs

● Operating temperature: ≤75℃

● Filter element material: glass fiber, SS304, SS316, polyester, wood pulp paper, PP, activated carbon, metal sintering

● shell material: cast aluminum, carbon steel, SS304, SS316L

Application range

● Compressed air piping

● Nitrogen

● Chemical plants, power plants, coal mines

● Electronic factories, hospitals, etc

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| >> Return | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

中文

中文 English

English